Tim Nelson

DELIVERING FIRST-CLASS CHANGE SOLUTIONS FOR PEOPLE & PARTS

Bluffton, SC

(682) 215-9585

mtnelson62@gmail.com

ABOUT ME

Expert problem-solving coach focused on guiding organizations to solving complex technical and behavioral issues. Invented Creative Logic™, an innovative process that pairs creative and logical individuals to gain synergy and improve parts, people, and productivity. Motivated to help those facing neurodiversity discover and gain empowerment from their gifts. All Shainin II® LLC services are Registered Trademarks.

Long-standing career with notable achievements including:

- One of two Red X® Fellows Worldwide

- Lockheed Martin Fellow Emeritus – First Quality Fellow in Corporation

- One of 25 Global Diversity & Inclusion Ambassadors Representing Dyslexia

- 2019 Quality Leader of the Year, American Society of Quality (ASQ)

CREATIVE LOGIC™ BRAND

Being Creative

Spearheaded resolution of 35-year-old issue for world-renown aircraft through use and improvement of problem-solving methodology. Read Full Story

Coaching Projects

Instrumental in leading teams to resolve complex technical problems across automotive, aerospace, electronics, and consumer product industries, accumulating 26,600 coaching hours throughout career. Read Full Story

Running Programs

Rolling Top 5® program implementation leads to the certification of more than 2,000 personnel from the world’s largest automotive supplier. Read Full Story

Improving People and Parts

Track record of improving both people and parts through universal problem-solving methodology. Read Full Story

Understanding Interactions

Identification of spike interaction between two mating parts leads to swift resolution of gas leaf blower motor issue. Read Full Story

Defining Standard Work

Awarded 2018 Quality Leader of the Year for significant contributions in Standard Work. Read Full Story

WORK HISTORY

Click on company below for more information

Owner/Founder | 2020 – Present

Develop and own technology for improving parts and people.

- Advised individuals coaching neurodiversity initiative at Daimler Trucks North America – the pioneer in autonomous trucks.

Quality Engineering Fellow | 2013 – 2020

Developed innovative solutions to complex, technologically challenging problems and supported C130 and rotary divisions.

- Instrumental in saving $1 billion by closing total of 65 Red X® projects.

- Certified 84 engineers in Red X® for the F35 aircraft – one of the most technological products in the world.

- Represented less than 1% of engineering population as Lockheed Martin Fellow.

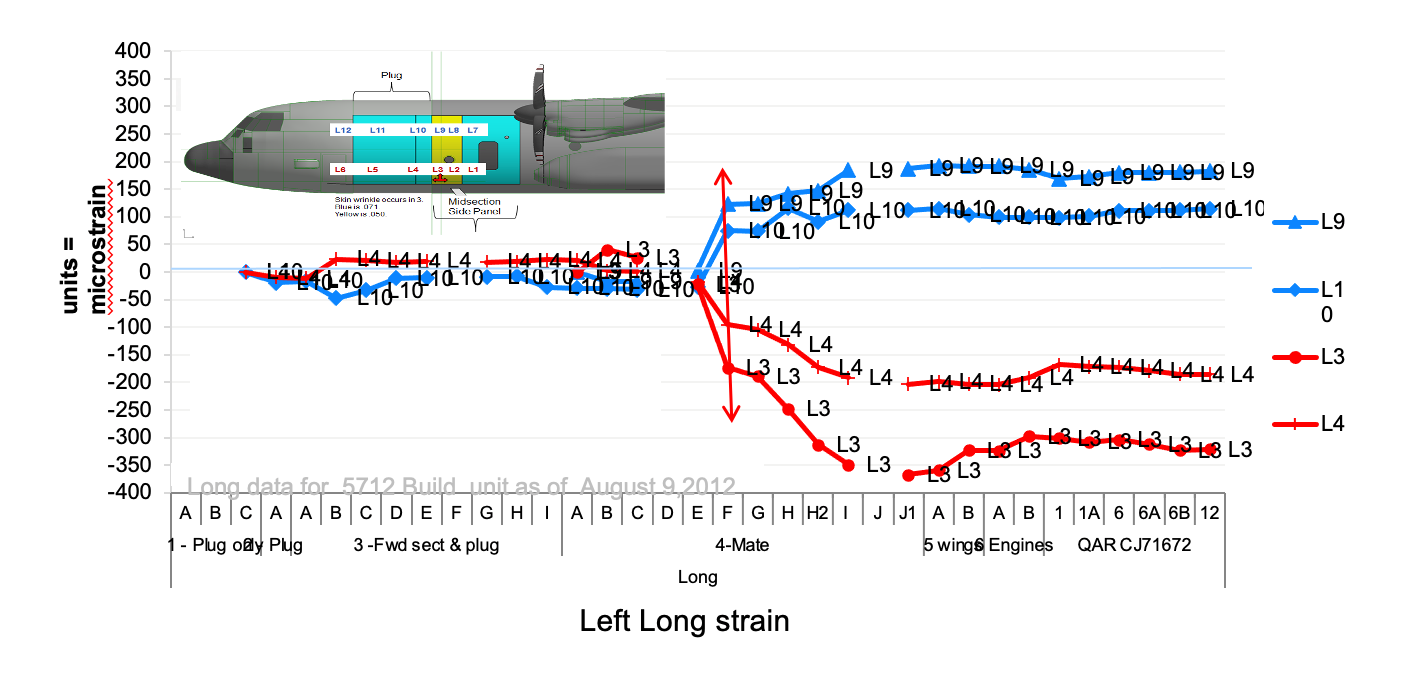

- Resolved 35-year-old problem through C130 stress reduction project that impacted 100% of aircraft.

Co-Founder/Fellow

One of four founding company members

- Recognized as one of only two Shainin® Fellows in the world – the highest technical designation in the firm.

Engagement Executive | 2008 – 2013

Worked with consulting firm representatives to integrate methodologies with clients, such as Red X®, Six Sigma, and Robust Design.

- Led consulting engagements with clients inclusive of Ford, Delphi, GM, Xerox, Andersen Windows, and Lockheed Martin.

President | 2006 – 2008

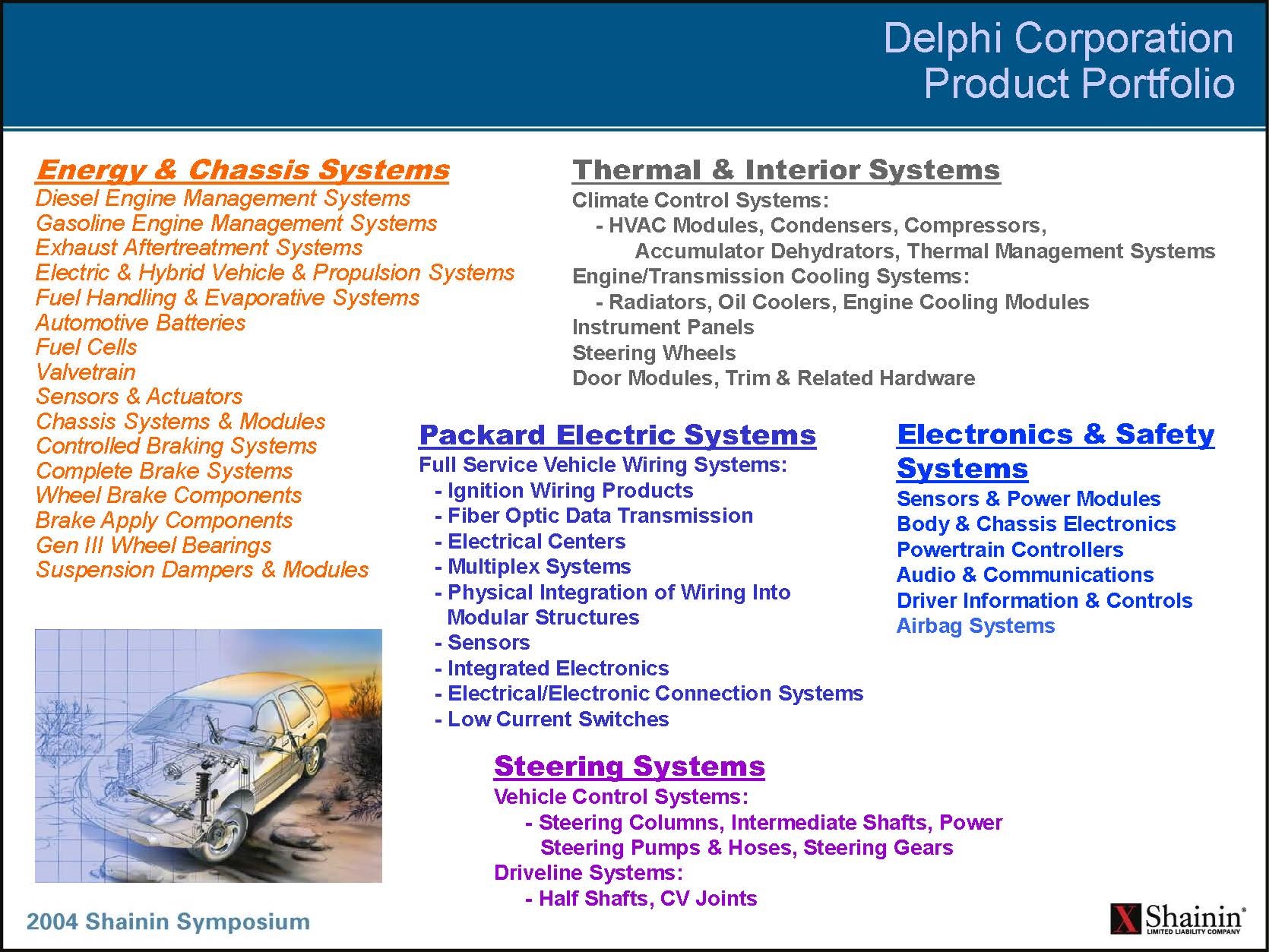

Managed Delphi Automotive account – the largest automotive component supplier in the world with 200,000 employees, over

150 plants, more than 30 technical centers, and numerous joint ventures. Supervised six principals and reported directly to CEO.

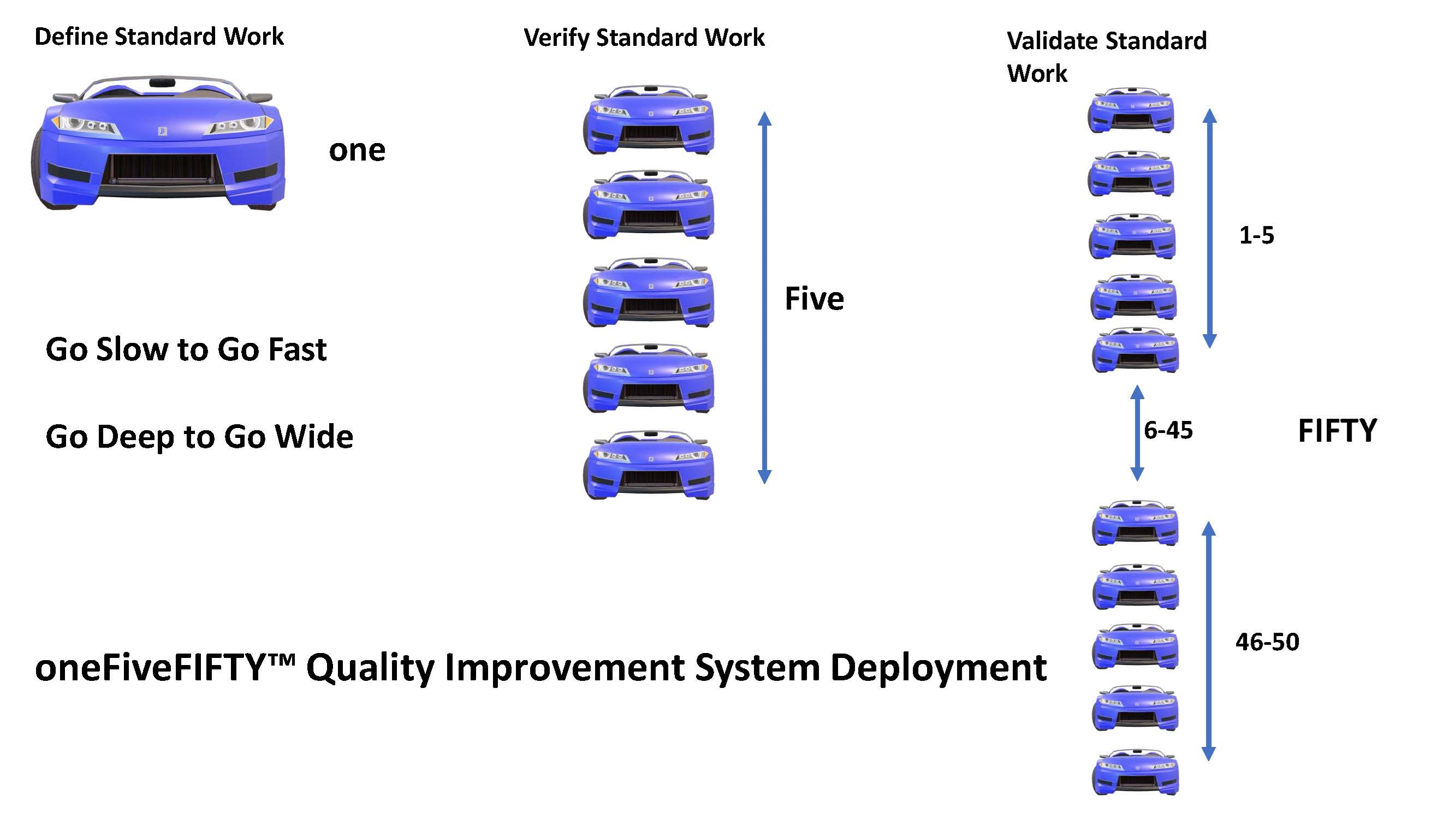

- Created Rolling Top 5® program to create accountability, reduce costs, and enhance capability and skills.

- Certified 2,000+ engineers in three methodologies through intercompany cooperative consulting.

Senior Consultant/Manager | 1992 – 2006

Solved crisis performance and output problems across automotive, aerospace, electronics, and consumer product industries.

- Advised client executives and coached GM teams and leadership on company’s “Hardy Perennial” program.

- Built relationships with international clients, such as Chrysler, BMW, GM, Ford, Delphi, Bosch, and Xerox.

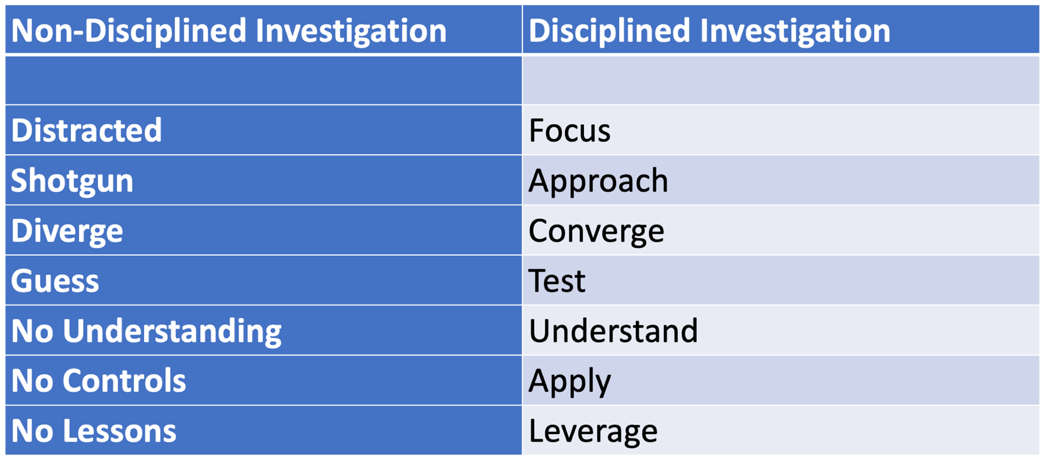

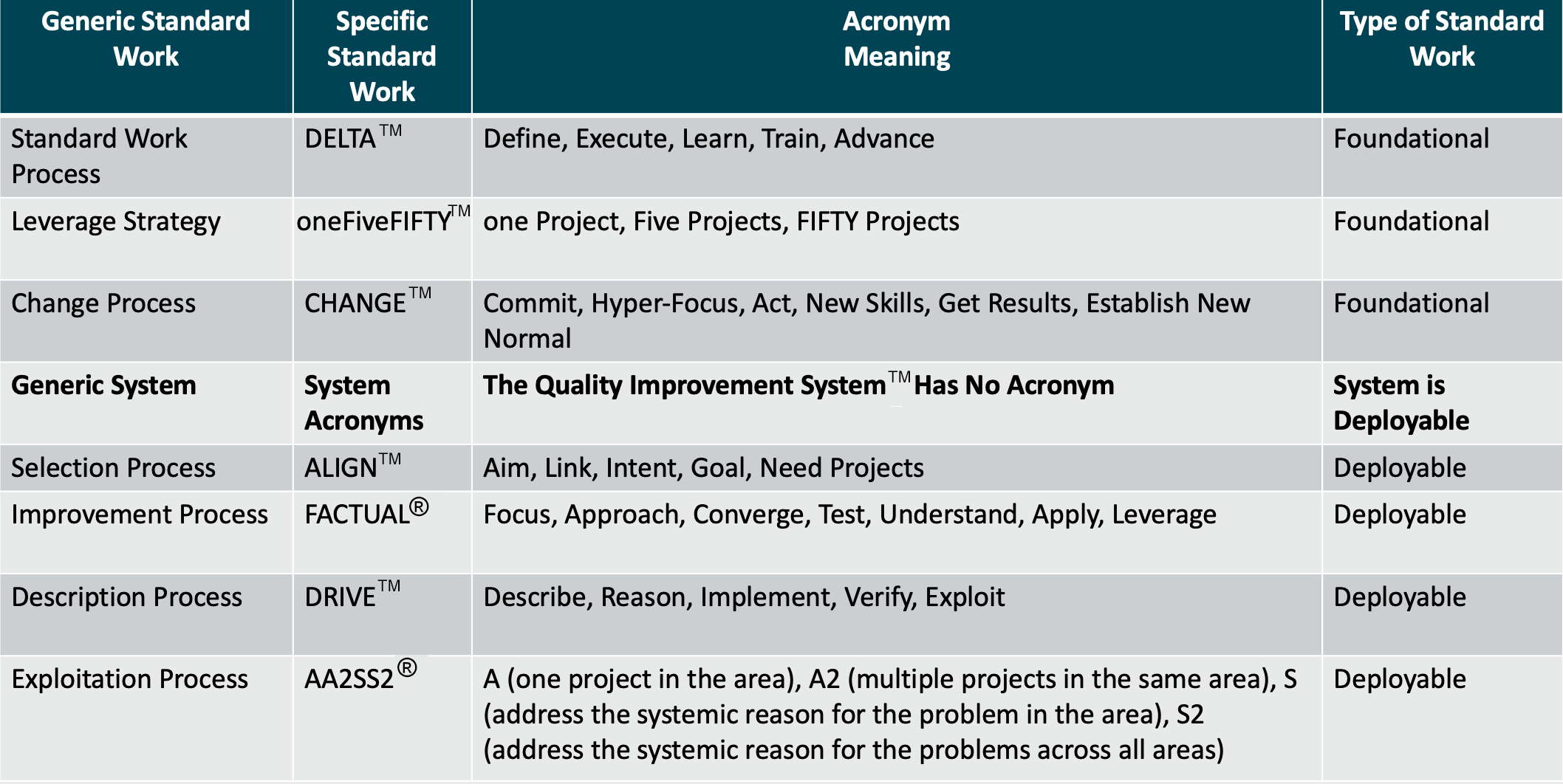

- Played significant role in evolution of Red X® as four-step improvement process and eventually FACTUALTM.

The largest automotive component manufacturer in the UK until Lucas Industries merged with Varity Corporation in 1996.

Internal Shainin® Consultant | 1988 – 1992

- Saved gasoline fuel injector plant, Nissan antilocking braking system product, and joint venture between Lucas and Sagem through application of exceptional coaching skills.

Product Engineering Support Manager | 1988 – 1990

- Developed in-house Shainin® class and trained both Lucas and BMW personnel.

Product Engineer | 1981 – 1988

- Improved engine efficiency by co-developing automotive camshaft and camshaft phasing mechanism.

EDUCATION & PROFESSIONAL DEVELOPMENT

Clemson University

Society of Automotive Engineers

Chairman, Carolina Section – 2 years

Outstanding Young Member

SAE Representative for Italian Automotive Industry in Italy

American Society of Mechanical Engineers

1st Place, Old Guard Competition – Outstanding Technical Content

2nd Place, Old Guard Competition – Recognizing Technology Development

Design News

Clemson Camshaft – featured in Top 10 Designs of the Year

Publications

SAE – Continuous Cam Lobe Phasing: An Advanced Valve Timing Approach

SAE – Development of a Variable Valve Timed Engine to Eliminate the Pumping Losses Associated with Throttled Operation

ASME: Variable Valve Timing for Diesel Compression Ration Control

Patents

Multiple U.S. & Foreign – Complete list available

Papers: NY Times, Boston Globe, Detroit News, Atlanta Journal, Greenville News (Local TV Stations)

Magazines: Automotive Engineering, Mechanical Engineering, Road and Track, Popular Mechanics, Design News, Sierra – Called to testify on fuel economy improvements using the Clemson Camshaft